Quality for Every Industry

Our Portfolio About SPM, Fixtures, Auto Gauges, Rapid Prototyping, Design Consultations , Low Cost Automations, Methods Engineering, Material Handling Solutions, IoT Consultations and Other Engineering Solutions.

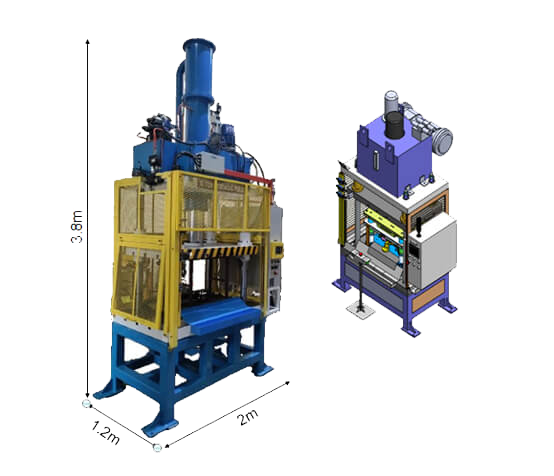

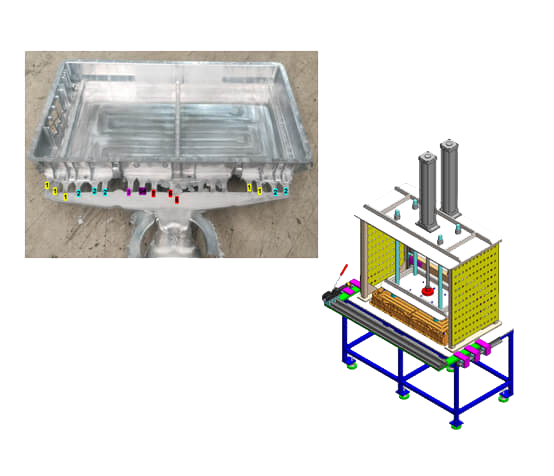

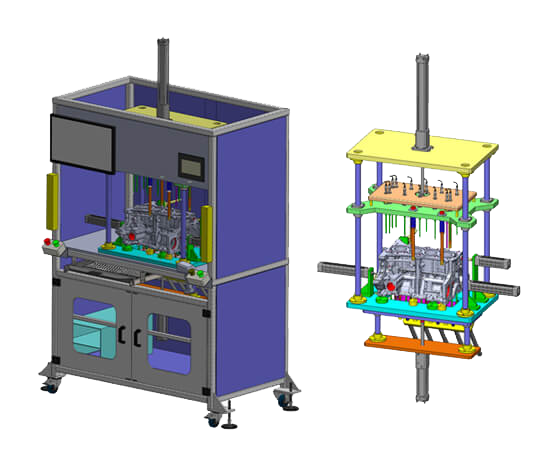

Hydraulic Press For Trimming Application

Integrated Power Pack with Heat Exchanger

Project : Trimming press 50T for ADC parts , with VFD

Specifications:

- Load – 50 Ton

- Stroke 900 mm

- Bed Size : 1000mm x 1000mm

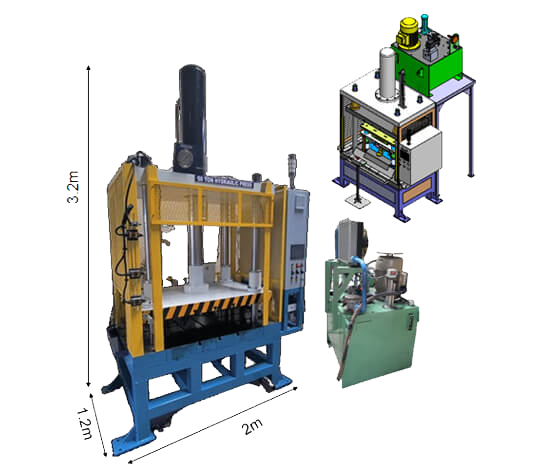

Hydraulic Press For Trimming Application

Separate Power Pack

Project : Trimming press 50T for ADC parts , with VFD

Specifications:

- Load – 50 Ton

- Stroke 900 mm

- Bed Size : 1000mm x 1000mm

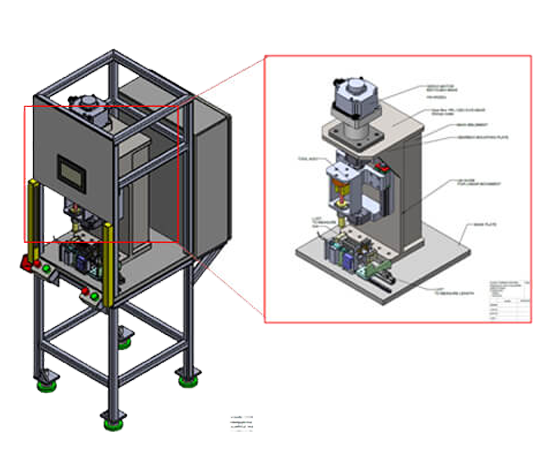

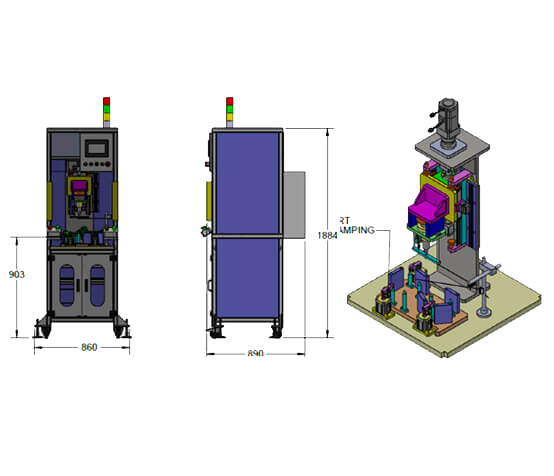

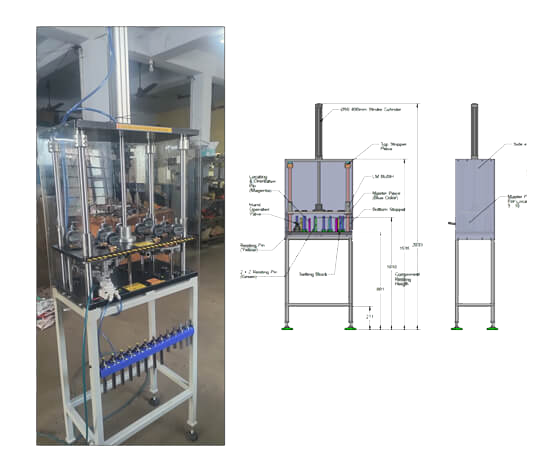

Needle Shaft Pressing SPM with Torsion Bar

Project : To press the needle shaft along the torsion bar with specific load and distance , Loading unloading Manual , With LVDT OD and Height Auto Check

Specifications :

- Load – 3 Ton

- Stroke 285 mm

- Rapid Speed : 48mm ~ 65mm/ Sec

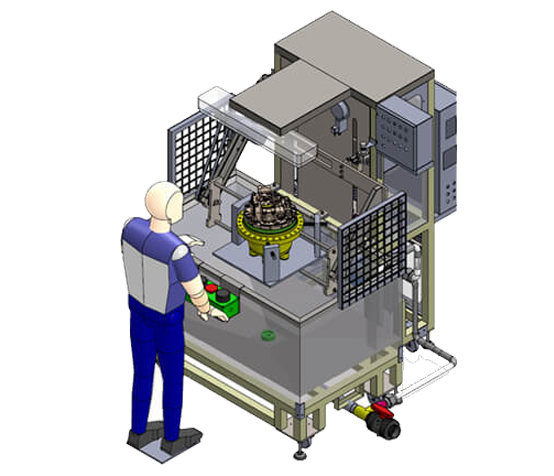

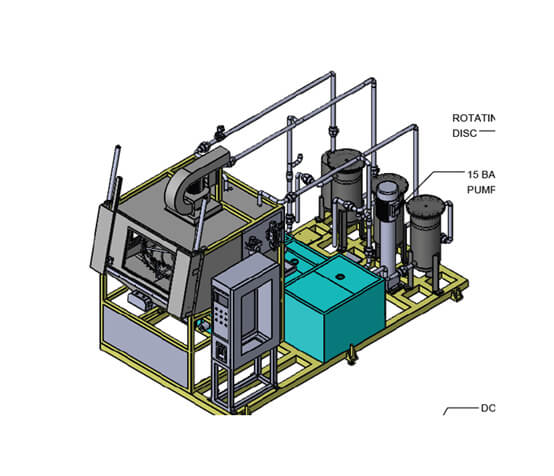

Leak Tester For Hydraulic Valve Assy For Earth Moving Equipment’s – Wet Type

Project : To Check the assy leak , using dunked type method , Using Water as medium.

Specifications :

- Leak Type : Water Dunked Method

- Job Size : 300 x 450

- Leak Pressure – 4~5Bar

Leak Testing Machine

Project: Leak Testing machine for ADC machined Part

Specifications:

- Dry Type LTM

- 1)Test Pressure 0.8 bar, 3 cc

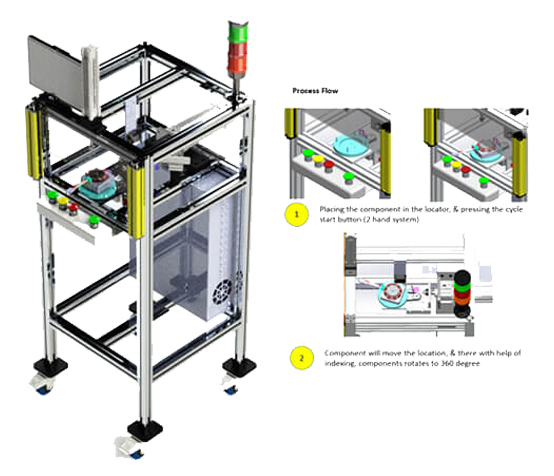

Air Gap Checking For Motor Assy

Project : Purpose of this machine is to use for checking the air gap between stator & rotor Using Vision and laser Technology.

Gate Cutting Fixture – Manual

Gate Cutting Fixture – Manual

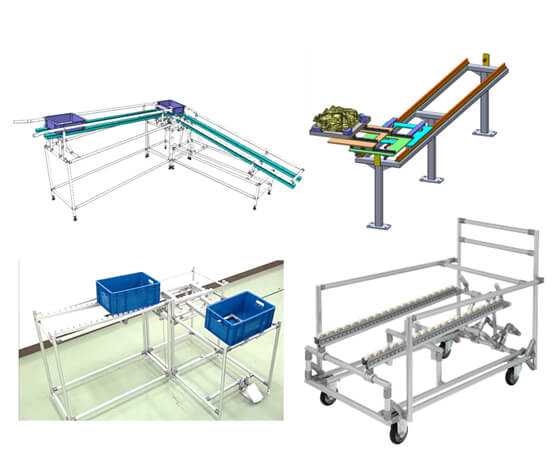

Material Handling System

Power Conveyors / Gravity Roller Conveyors

Material Handling System

Karakuri (Gravity / Low Cost Automation Mechanism Chutes)

Servo – Bush Pressing SPM

Auto Receiver Gauging with position conformations with traceability

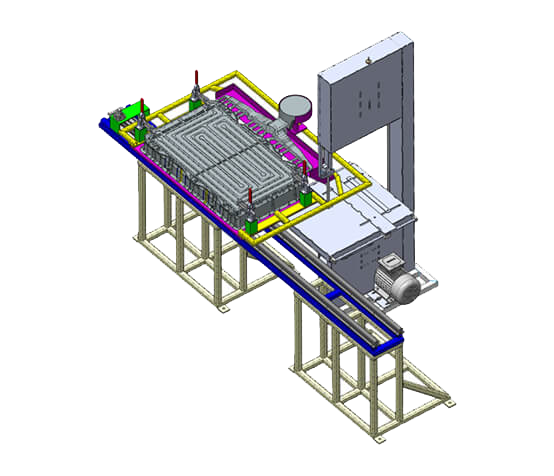

Industrial Washing Machines – Single Stage

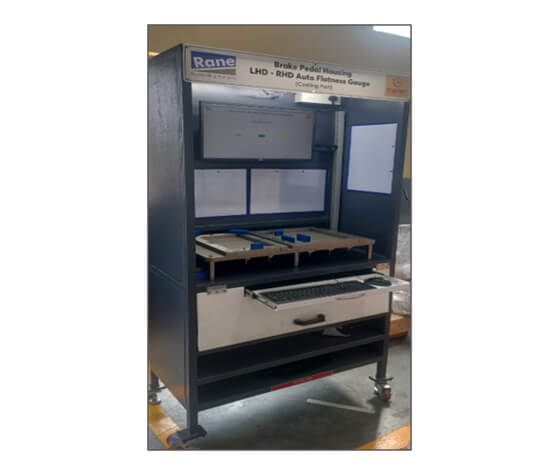

Auto Flatness Gauge – With DAQ

Specifications :

- To Check the flatness of component Using LVDT Probes

Flatness Inspection Gauge Manual

Project : To check the flatness of the cover engine part Spec 0.5 using Dial method.