MES in Industry 4.0 – Connecting Machines for Real Manufacturing Intelligence

Empower Your Factory with MES and Machine Connectivity

Unlock real-time insights, eliminate downtime, and gain total traceability by integrating your

machines with a Manufacturing Execution System (MES) built for Industry 4.0.

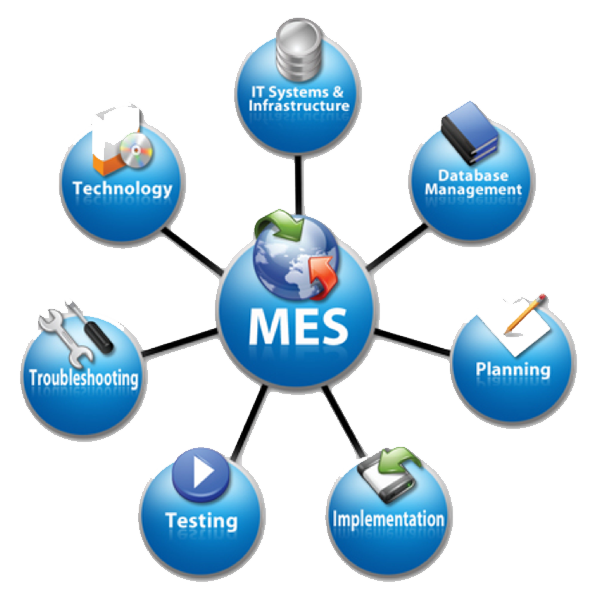

What is MES in Industry 4.0

The Digital Backbone of Smart Manufacturing

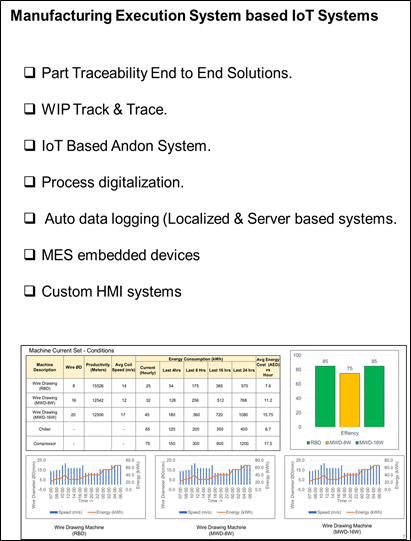

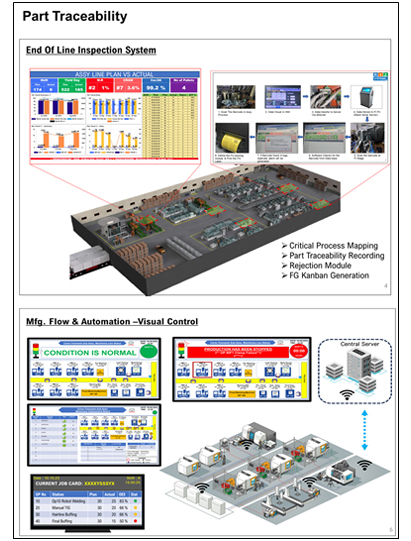

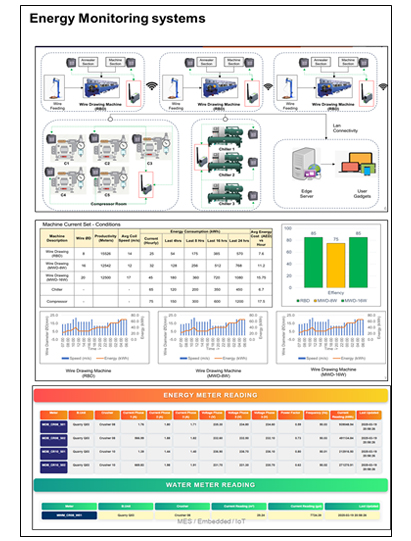

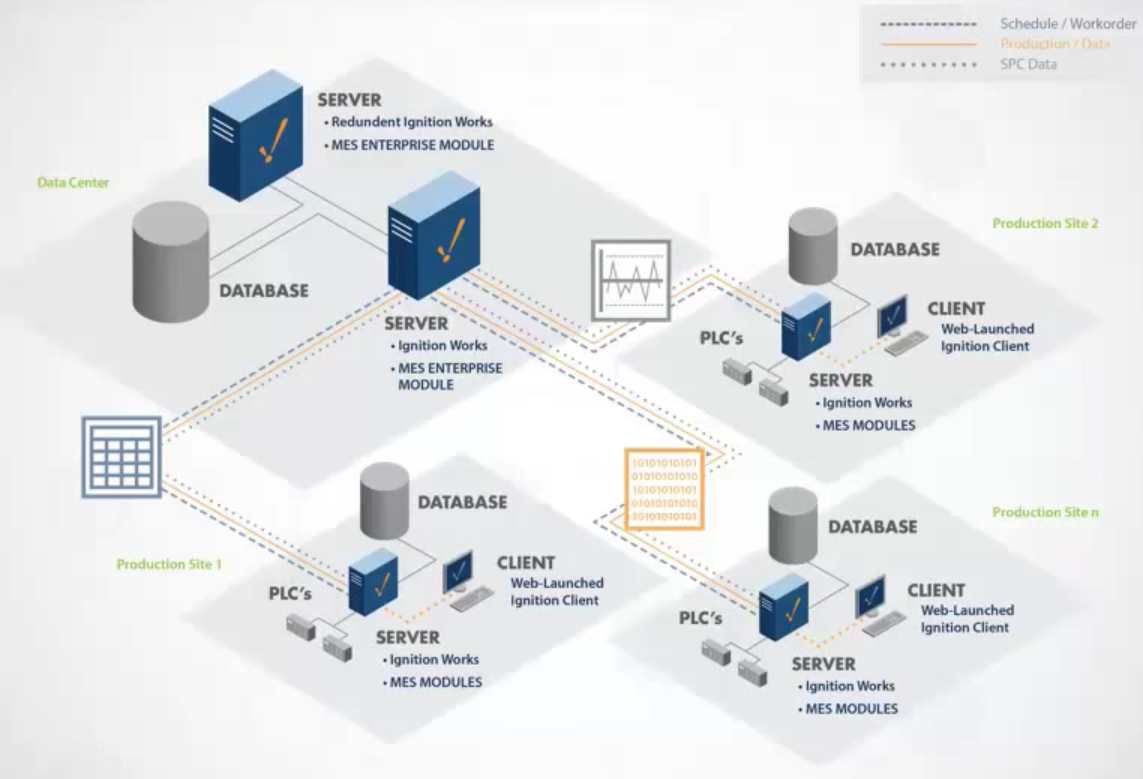

Manufacturing Execution Systems (MES) are the heart of Industry 4.0 — bridging the gap between the shop floor and enterprise systems.

By connecting machines, PLCs, and sensors to a centralized MES platform, manufacturers achieve real-time visibility, automatic data collection, and synchronized control across production lines.

MES integrates seamlessly with ERP and cloud analytics systems, enabling data-driven decision-making and continuous improvement in production efficiency, quality, and traceability.

Our iOS-based MES empowers real-time visibility and control across the production line. Seamlessly integrate machines, people, and data for smarter, faster decision-making.